Managing Fall Grain

When harvest is in full swing, we know your top priority is keeping the combine moving and getting the crop out of the field. However, a successful harvest can quickly be ruined if stored grain is not properly managed in the fall and winter months. The first step to ensure grain quality should occur before the crop even enters the bin.

Sweeping and getting any other dirt and dust out of a bin before it’s filled can play a huge role in grain quality. It is also helpful to apply insecticides around the bin area to help prevent moths and other insects from feeding on the grain. Our go-to product for moth and beetle prevention is Malathion 5EC. After the bin has been swept and cleaned out, spray the mixed product on the entire inside of the bin, as well as around the exterior of the bin. Typically, one gallon of mixed product will cover 1,000ft2. For bins with stored grain, we also recommend INSECTO. Apply one to two pounds of INSECTO per ton of grain to the top two-to-three feet of the bin to control a variety of insects.

When the grain is harvested, managing the moisture percentage is key. For grain that will be out of storage before spring, moisture can be 15.5–16% for corn and 13% for soybeans. If grain will be stored through next summer, corn moisture should be below 15.5% and 11% for soybeans. A general rule of thumb is the longer the grain will be in storage, the lower the moisture content needs to be.

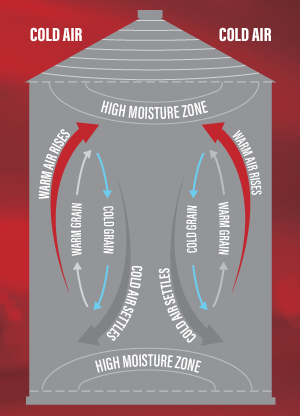

When grain moisture is good to go for fall and winter storage, it is time to cool the grain down to prevent moisture migration. We talked about this concept in our Spring Grain Management article earlier this year; moisture migration is just as much of a risk to grain quality in the fall as the spring. If the grain goes into the bin warm while the outside air is cold, this temperature difference will cause moisture to accumulate at the top of the bin. The ideal temperature for stored grain in the fall to winter months is 30-40°F. This temperature can be achieved by running the fans in several stages.

In each stage, it’s important to completely cool the grain throughout the bin, as the moisture can condense between the cooler and warmer areas. We have programs from our suppliers that can calculate the estimated time it takes to cool down the grain. If you provide us with the bin’s diameter, eave height, fan type and horsepower, we can tell you how long to run your fans.

In each stage, it’s important to completely cool the grain throughout the bin, as the moisture can condense between the cooler and warmer areas. We have programs from our suppliers that can calculate the estimated time it takes to cool down the grain. If you provide us with the bin’s diameter, eave height, fan type and horsepower, we can tell you how long to run your fans.

Example: A level full 48’ diameter bin with an eave height of 28.3’ (8 ring, 4” corrugation) and a 7.5 horsepower, 1750 rpm centrifugal fan will take approximately 54.6 hours to cool the grain 10-15°F throughout the bin.

Moving through the fall and winter seasons, bins should be checked at least once per week. With the higher commodity prices we’ve seen, it is well worth your time to make sure the quality is maintained in your high-value crop. We also recommend turning on the fans every so often, even if you think the grain was properly cooled down. Not only does it give another opportunity to stop moisture migration, but you can also smell the air that first comes out of the fan. If the air smells musty, you may have some spoiled grain, which is much easier to handle when it’s caught early.

If you have any questions on fall grain management, give Roger Slaughter or Tom Miller a call. We wish you a productive and successful harvest season!