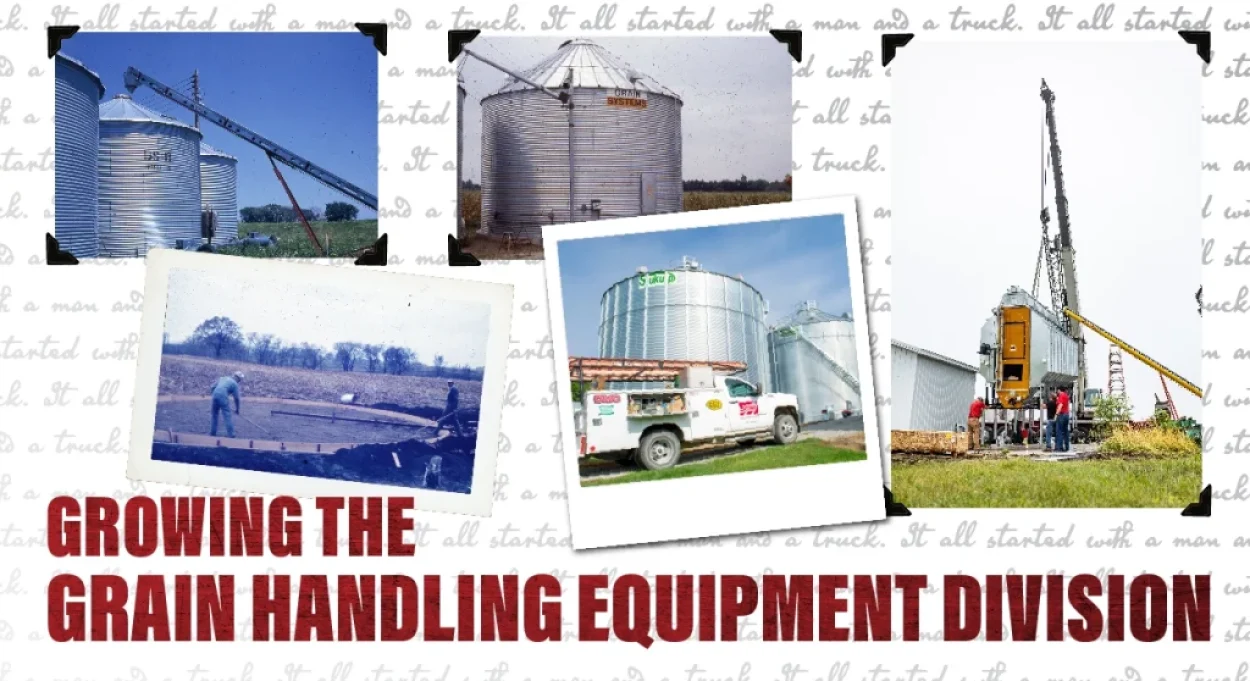

Growing the Grain Handling Equipment Division

Identifying opportunities is just as much of a cornerstone to Stutsmans as serving customers for success is. As gas-powered combines and shelled corn started to become more popular in the post-war ’50s, on-farm grain bins started coming onto the scene. Recognizing the opportunity to pioneer the selling of grain storage and drying equipment in southeast Iowa, Eldon brought on the Black, Sivalls & Bryson (BS&B) line of bins. At this time, Butler was their biggest competitor.

Hitting the ground running with this new product line, Ralph Troyer (our first livestock equipment specialist) installed the first in-bin drying system in the area. Within years of entering the grain storage equipment sector, we brought on Bazooka Grain Handling System’s (Salina, Kansas) augers as well as fans, heaters, stirrers and conveyors from a newly formed, family-owned company that you may have heard of … Sukup.

“We have always had a natural synergy with Sukup; two family-owned companies with similar values,” said Roger Slaughter, Special Project Lead. “It’s really no surprise we have maintained our relationship with them since the start of our dealings in this sector.”

Jim Stutsman, the third son of Eldon and Dorothy Stutsman, made his entrance into the company by building and servicing those same grain bins at the age of 14. By the time he was 16, he was training crews on how to construct the bins all over eastern Iowa.

Grain Handling Equipment Expands

From pouring the cement to bin erection, the Stutsman team handled the entire construction process. During the days of BS&B, we sold 18′, 24′, 27′ and 30′ bins ranging from 3,500 to 10,000 bushels. Over the next decade, there were a lot of changes with bin manufacturers (BS&B to Reed Joseph bins to York) before we landed on Chicago bins, fans and heaters. In fact, we were one of the first suppliers to introduce and sell the Chicago portable dryer, well before portable dryers became popular. However, being first isn’t all that it cracked up to be.

“Those Chicago portable dryers were the nastiest thing to change a motor in,” said Roger Slaughter. “When the aluminum fan blades would corrode, they’d fuse to the steel shafts, and you’d really have to pound on them just to take the fan blade off.”

Eldon “Shorty” Slaughter, our handy grain bin serviceman, had an innovative solution for this: ask his friend with a hook for a hand to help break them free; in the case of a mallet slip, it was the metal hook getting hit and not a hand.

The move from York to Chicago bins wasn’t the only transition happening in the ’70s. While Ralph started backing down to part-time, Roger Slaughter started taking the lead on this division. After calling on us for years, Grain Systems, Inc (GSI) of Assumption, Illinois, persistence, over-purchase of bin roofs and the start of Chicago Eastern Bin’s demise (lawsuit troubles led to their eventual bankruptcy) created the perfect storm. After getting stuck with more bin roofs than they needed, GSI offered Jim Stutsman a unique deal to get their foot in the door. If we bought multiple bin roofs up front, we could order side walls as we needed them, all at a discount. This deal paved the way for our relationship going on 40 years to date. As our experience grew with this sector of the industry, we learned the value of having a variety of brand options to protect against the manufacturer’s limited supply or long backorder wait times. With this, we added Shivvers drying products and augers to diversify our offering.

Grain Handling Division Today

Although the grain handling equipment division looks very different today, mostly with the technology and sheer size of products offered, there are a few things that remain the same. GSI, Sukup, and Shivvers have stood the test of time and continue to be our leading brands, Roger Slaughter and Tom Miller are still at the helm of this division ensuring our bin customers receive the cornerstone Stutsman service, and we continue to evaluate new technology/products/opportunities to ensure we are offering innovative solutions.