Growing The Feed Ingredients Division

After receiving requests from his neighbors to bring supplies back from town, Eldon Stutsman realized there was a need for a feed supply business. Even though 1934 was a less-than-ideal time to start a business, Eldon started transitioning his milk route deliveries to feed supply deliveries. Little did he know how much change and growth his business, including the feed ingredients division, would experience in the next 90 years.

Growing a Family and a Business

While the economy was clawing its way out of the depression and Eldon’s business was slowly starting to turn its wheels, there were more than just hard times to fuel Eldon’s fire to work harder. On top of marrying his local sweetheart, Dorothy Amish, on August 3, 1937, they now had a farmstead of their own to call home, just miles in between where they grew up. This new chapter allowed Eldon to stock feed supplies from his outbuildings, as well as have a few dairy cows of his own.

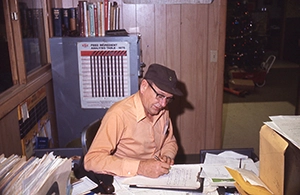

Enter Clarke Meer

After coming home from WWII, Clarke Meer, a journalism major from the University of Iowa and one of Eldon’s former classmates, was looking for a part-time job. He told Eldon he’d be able to work until he got a full-time job in the newspaper business. Although Clarke was a freelance photographer for various newspapers, he kept sticking around to help … for 38 years to be exact. If only he knew at that time, he would spend the rest of his career leading the feed department and being instrumental in the growth of the Stutsman business.

Right Place, Right Time … Or Rather Wrong Place, Right Time

Sometimes life is about being at the right place, at the right time.

J.C. McDaniels, sales manager for Schreiber Mills out of St. Joseph, Missouri, had heard about a guy by the name of Eldon Stutsman who would pick up feed from Hummer’s Feed Mill in Iowa City along with other supplies (like groceries) for community members.

As luck or perhaps fate would have it, J.C. was trying to track down Eldon when he landed on Roy Lackender’s farm (1/2-mile south of Eldon’s homestead).

“What do you need to talk to him about,” inquired Roy.

After giving the spiel on Schreiber Mill’s Sweet Lassy Feeds, Roy said if Eldon ended up bringing on the line, he would take five tons. When J.C. found Eldon, he told him, “I sold five-ton just looking for you!”

Roy was a well-known Hereford feeder at the time. The Lackender family is one of our longest customer/family relationships starting with Roy, to his son Russel, to now his grandson Doug and granddaughter Janet.

Sweet Lassy became a significant part of the operation and really the famous cornerstone for the Stutsman feed business. The Schreiber Mills’ patent on pelleted feed really catapulted the business; Stutsmans was the only one to offer the popular pelleted feed at that time.

As the growth of the Sweet Lassy business took off, two things became evident: transportation was a bigger need, and it was time to move closer to the rail to receive product.

Headed for Hills

After 15 years of running the business from just a truck and outbuildings on the farm, Eldon purchased some land in Hills (6.5 miles east of the farm) and put up his first warehouse in 1948; barns on the farm were still used as extra warehouses until enough room was built in Hills. Although the move itself was a major benchmark, direct access to the Rock Island Railroad opened the door to a whole ‘nother level of opportunities for the entrepreneur.

The move to Hills would pay off early on, in more ways than one. As many local farmers started moving away from livestock production, and the demand for Sweet Lassy products continued to grow outside our regional retail crowd, eventually, Eldon transitioned from a dealer to a distributor in the 1950s.

As we transitioned from dealer to distributor, Clarke Meer was instrumental in establishing our dealer network. Dealer number one was Wellman Produce; we are proud to say they are still a customer today.

The added capacity also brought on some additional staple products like Kraft’s buttermilk cheese byproduct and Morton Salt.

Railroads & Silver Dollars

What do a railroad, silver dollars and a St. Joseph, Missouri, TV station have in common? Eldon and a Sweet Lassy trainload promotion.

With direct access to the railroad and some creative thinking, Eldon held a unique promotion that would become a popular tradition for years to come. Eldon brought in a trainload of Sweet Lassy, and everyone who bought right off the train would get a silver dollar for every ton purchased.

“I remember it was a lot of work to get those cars empty,” said Chairman of the Board, Ron Stutsman. “We only had a couple of days to get them emptied. Some neighbors would even come in to help unload cars.”

For corporate promotion purposes, Schreiber Mills had a St. Joseph TV station cover the event with aerial photos and videos, to showcase the event to other dealers.

Decades later, Hills Bank found a large bag of silver dollars in their safe that were left over from the popular event.

The Feed Department Grows

With feed sales growing, the team needed to grow as well. The feed department was managed by Clarke Meer with Hank Foster as the lone salesman. In October 1979, the sales team doubled when Terry Hurshman came on board. The first two weeks were spent training in the warehouse learning the ins and the outs of the growing department.

“Back in 1979, we covered a small territory in central and eastern Iowa. Every town had a feed store, some would have two or three. In a single day, you could make 15-20 calls without traveling 100 miles,” recalled Terry Hurshman. Today, we are servicing 10 states and have nine sales reps. Dependent on the area of course, a sales manager may travel 200-300 miles to call on only five accounts.

At a time of growth, Clarke Meer, feed division leader, was a visionary.

“‘I remember in my first few years here Clarke purchased a pallet of wild bird mix. At the time we sold cattle, swine and poultry feed as well as ingredients used to manufacture those feeds. Eldon was a little perplexed in this decision to purchase a ‘whole pallet of bird feed.’ I remember Eldon asking Clarke ‘why are we purchasing a pallet of bird feed?’ Without missing a beat, Clarke replied, ‘We are going to sell it.’ At the time it seemed a little risky as we had never sold a bag of bird feed, and feeding birds had not caught on yet in the marketplace. In fiscal 2023, we sold 1,225 ton of bird feed and related items,’” added Terry Hurshman.

Upgrading Our Fleet

The feed ingredients division jumpstarted the conversion from paddy boards to forkliftable pallets. This greatly improved efficiency at the loading docks. We also moved away from straight trucks and 30′ van trailers to 48′ and 53′ trailers. With the upgrade, we were able to maximize load efficiency to and from our customers. Load efficiency became even more important as the feed industry consolidation led to our division expansion. We were no longer solely servicing feed stores in eastern Iowa; to continue our growth we had to reach out further. In the 1990s, we began to service businesses in northwest Iowa, southern Illinois and Wisconsin. With the territory expansion and delivery routes that required a multi-day run, we added sleepers to a few route trucks.

Dedicated to Setting the Bar Higher

In order to continue providing the exceptional service that is the company cornerstone, the feed division knew a warehouse expansion was direly needed. In 2003, a 30,000 sqft warehouse was constructed north of the scale house. With six docks and the additional capacity, we were able to more nimbly serve customers and continue to diversify our product line.

The added capacity also led Terry Hurshman, Terry Yoder and Scott Stutsman to evaluate how we could provide better support to the growing customer base and to make it easier to do business with Stutsmans. Doing something a little different than our feed distribution competitors, the first dedicated, in-house customer service representative was hired in 2008.

Division Today

Not only has our reach expanded, but the sheer volume of products we move has also increased. This added volume improved our purchasing power and how we are viewed in the industry by our suppliers. The 2020 feed warehouse construction added 60,000 sqft of storage and 16 more docks for a total of 29 loading docks. On top of improved load/unload efficiency, the additional space created opportunities to continue expanding our product offerings as well as improve our purchasing positions. Overall, the added growth has improved our ability to service our customers, maintain competitiveness in our market and strive for continued growth.

Today, the Stutsman feed department serves 1000+ customers across ten Midwest states with nine territory sales representatives, four customer service specialists, four product procurement managers and nineteen dedicated delivery trucks.