Evaluating Krone Conditioner Options

By: Derek Bontrager, Equipment Sales

When it comes down to it, getting the highest return on investment is key, and Krone kept that in mind when designing and building their forage equipment. To accomplish this mission, Krone has made sure to not just build high-quality equipment but to offer multiple conditioning options on their pull-type, mounted and self-propelled mower conditioners. Here’s a breakdown of the three types of conditioners: rubber rolls, steel M-rolls and V-tines.

The rubber rolls are nearly 10” in diameter and mesh together in an interlocking chevron pattern. Both rolls are driven via separate gearboxes and synchronized to provide uniform conditioning across the width of the rolls. The top roller is suspended from a spring assuring consistent pressure while allowing for objects to pass through trouble-free. Rubber rolls provide both crimping and crushing action to condition hay; they are especially effective for finer-stemmed plants, like grass or alfalfa.

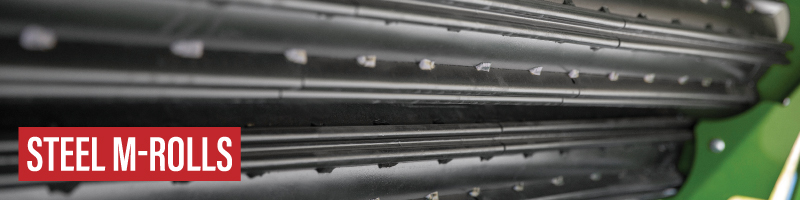

The steel M-rolls are aptly named due to their M-shaped design. M-rolls condition like rubber rolls but offer a more aggressive crimp on the crop. They work quite well in heavy and wet crops like alfalfa or alfalfa grass mixes. The almost 10” wide M-rolls are also effective at drying out stiff or thick-stemmed crops. The rolls speed up dry-down by creating uniform crimps without bruising leaves. Steel rolls are very durable and require little maintenance.

As their name suggests, the Krone V-tines are a V-shaped hardened steel tine that pulls the crop off the cutting discs and rubs it against a diamond tread-covered conditioning baffle. V-tines can be run at two different speeds: 600 or 900 RPM. The speed is easily changed with a simple lever on the tine gearbox. The 600 RPM is used for less intensive conditioning or for leafier crops like alfalfa or clover. When cutting alfalfa hay blends, the conditioning baffle is set to the raised position so it doesn’t strip off the alfalfa leaves. When cutting grass hay, the V-tines can be set to 900 RPM and the conditioning baffle set to the lower position to strip the waxy coating more aggressively from grass. The pivoting V-tines allow foreign objects to easily pass through compared to rollers. V-tines span the entire working width of the cutterbar, and their helical arrangement provides for continuous crop flow. Adjustable deflectors can be set to spread material across the full cutting width or in a narrower swath. V-tines consume the least amount of horsepower compared to other conditioning types.

I have personally always been a fan of roller conditioners—especially steel rolls. They do an excellent job of crimping and cutting down the drying time in wetter, heavier crops. Although, I was pleasantly surprised with Krone’s V-tines after seeing them in action this past summer. While they might require a bit more management, they offer similar conditioning to rolls in a mechanically simpler arrangement.

We were recommended to try V-tines by our Krone rep, Tom Hopkins. Tom has extensive experience with V-Tines while working for Krone in England, southwest Wisconsin and throughout the upper Midwest. “Krone’s V-tines work where other conditioners do not thanks to their massive 25” diameter. They can condition alfalfa to tall Sudan grasses and everything in between,” said Tom. “Due to accelerated crop flow even light hard-to-cut materials, such as wheat straw, gets cut and pulled through the machine with ease. V-tines are also a very cost-effective option.”

While Krone has set out to manufacture high-quality equipment, it is always our goal to make sure you find the piece of equipment that best fits your forage needs and gives you the greatest return on your investment.