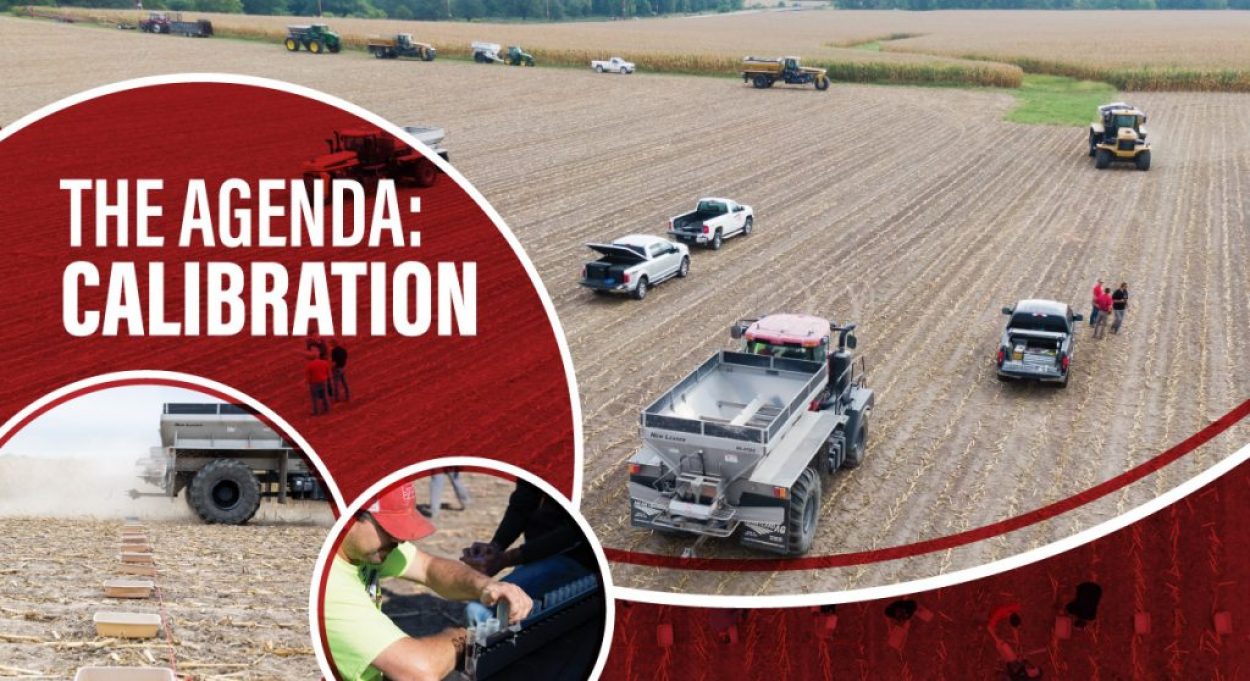

The Agenda: Calibration

It was a meeting of all the dry-spreading equipment from our Hills and Wellman locations along with the fleet from K&B Ag in Fairfax. Driving by on that mid-September day, you might have wondered why there were so many machines in one field. However, if you looked closely, you’d notice the team of Stutsman employees conducting spread pattern testing or pan testing.

The Set Up

Before heading out to the field, each of the machines went through a catch test to verify rate output accuracy per the controller. From there each dry spreader was sent out to the field to run on the 120’ wide test course set up with 22 collection trays spaced every five feet, with a center collection tray added for four-wheeled spreaders.

The Spread Pattern Test

Using weights from the catch test, applicators set their spreaders for the desired material density. In the field we conducted three different tests: a single product application, a blended product application and a blended product application containing cover crops. After the spreader ran the course, the collection trays were carefully emptied into test tubes and evaluated.

The Outcome

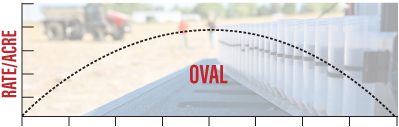

This pan testing allowed us to look at a few different things. First, the testing illustrates how the product is being distributed across the spread pattern, as well as the distance the various products are being thrown from the center of the machine. Ideally, we want an oval distribution. If the pattern deviates from the desired pattern, we can adjust several settings on the machine, like spinner speed. Additionally, with blended products, we examine the contents within the test tubes to make sure there is consistency across the swath.

The Value

We apply a variety of dry products for our customers ranging from urea to lime with each product having a different bulk density. By conducting catch tests and spread tests annually, or any time we add a new product, we can ensure products are being applied accurately across your fields.