The Pursuit for a Better Way: Story of Iowa-Made Swivel King Hitches

According to Thomas Edison, “to invent, you need a good imagination, a pile of junk, and also getting fed up from breaking manure tank hitches.” Okay, maybe Edison didn’t mention manure tanks and their traditional hitches in his quote, but it’s with this innovative spirit and frustration that Swivel King hitches were born.

Luke Jaeger of Keota, Iowa is certainly no stranger to manure application; he has been in the custom pumping business for over 17 years. What started as an opportunity to buy a producer’s manure tank and take care of his application needs, has now turned into a three-tank operation; Luke currently runs two GEA 9500s and one 10500.

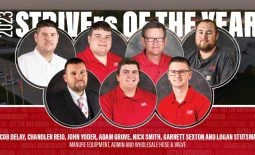

When Luke broke his first hitch during the fall 2019 season he thought ‘there must be a better way to do this’ but when breakdowns two, three and four happened it went from ‘there must be a better way’ to ‘I’m going to find that better way’. “I remember Luke was in the office because yet another broken hitch (he had a bad run with hitches that fall) and him saying he was going to have a new hitch solution by the end of the year,” recalled John Yoder, VP of manure equipment. “And he did.”

As the fall season wrapped up, he went to Kyle Moore of Schaus Vorhies Manufacturing (Fairfield, Iowa), to figure out viable solutions. As luck would have it, this wasn’t the first time that Kyle had worked on a manure tank hitch; he had ideas for years on ways that the hitches could be improved. Within minutes of talking options, Kyle had a sketch on a piece of cardboard of what would become the Swivel King. Surprisingly, the first hitch prototype was spot-on (however, it would take seven attempts to perfect the steering mechanism). “Kyle told me ‘you know you could sell these’. I didn’t believe him, but I guess he was right. I was just concerned with preventing my hitches from breaking,” said Luke.

An 80-million-gallon trial

So, when Luke followed up with John on what he and Kyle came up with, John was excited about helping other applicators out, but as with any product we bring on, he wanted to make sure these hitches were the real deal before giving our stamp of approval. Luke ran the first prototype on one tank in the spring of 2020, then added them to the rest of his fleet as well as four other local manure tanks that fall. This 80-million-gallon trial passed everyone’s expectations with flying colors.

When navigating steep terrain like waterways or ditches, instead of stressing the hitch, the Swivel King flexes to the environment allowing for 45-degree movement up and down. On top of preventing the costly downtime and repairs that come from broken hitches, Swivel King hitch users have reported the peace of mind and sense of security that comes with the more stable/secure road travel. Customers have also shared how pleased they are with how much quieter the Swivel King is over traditional hitches. This performance has been enough to get people talking. As we’ve gotten more Swivel Kings out in the field, users have been eager to share their experience with other tank operators, and we’ve seen their popularity continue to snowball.

The last hitch you should have to buy

When asked what makes the Swivel King unique, Luke responded that it’s the last hitch you should have to buy. He added that with Kyle’s machinist background, they are built so every contact point is greaseable and rebuildable.

Other Swivel King features:

» Made to fit any drawbar

» Currently specific to only GEA Houle tanks. Thanks to GEA Houle’s consistent design, Swivel Kings will fit on all models.

When we come across a product or service that will solve customers’ problems, we get excited; even more so when it comes from people who work in the manure industry and understand it at a deeper level. Add in the fact that it’s a home-grown, Iowa-made product, and that’s just the cherry on top.