GrainTrac: Ensuring Quality with Grain Temperature Monitoring

You’ve gotten the grain out of the field. It’s been dried to the desired moisture and now it sits … in a bin, just waiting.

Why Grain Temperature Monitoring Matters

You’ve done everything as recommended leading up to this point. However, while grain could enter the bin at the suggested moisture and within the ideal temperature range, continuing to check the grain temperature while in storage is the other measure to help prevent loss to spoilage.

Iowa State University Extension and Outreach reports that more and more grain goes out of condition every year due to uncontrolled temperatures. The goal is to keep grain within 10-15 degrees of the outside temperature. To help control the bin environment and meet this goal, biweekly (colder months) and weekly (warmer months) temperature readings should be taken.

While the methods to check temperature are as simple as checking the fan temperature sensor or as time consuming as climbing up to the top of the bin and probing the grain (and also checking for condensation), you are relying on sometimes a single reading for the entire bin. That’s where GrainTrac comes in.

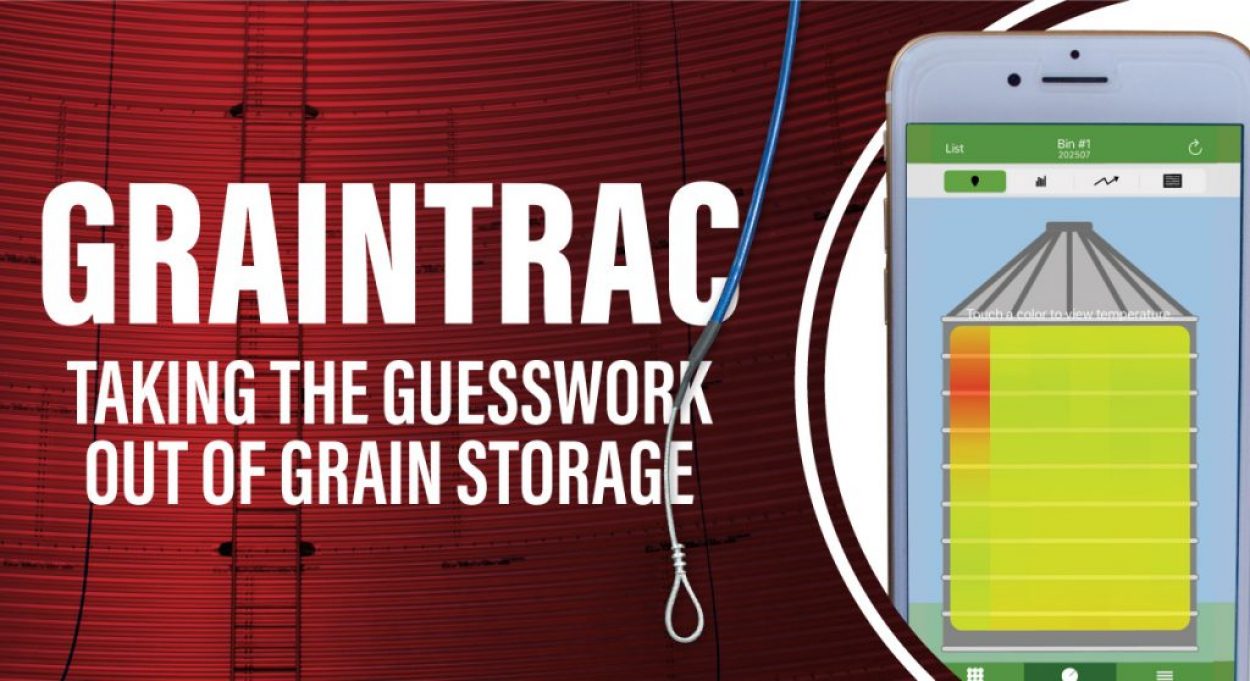

GrainTrac: Modernizing Grain Temperature Monitoring

This new system from Tri-States Grain Conditioning, Inc. monitors grain temperature from multiple sensors placed throughout the bin. Temperature readings can then be checked at any time, anywhere.

Using a cellular signal, the sensors will take a reading four times a day and report it to a secure website. The data can also be accessed through an app on a smartphone or tablet. However, not just one temperature is reported. With multiple sensor cables running throughout the grain, each cable reports temperatures for its given region. The number of cables per bin is individually determined and placed strategically throughout the bin. For example, a bin that is 60’ in diameter would have one cable in the center and 10 others placed around the bin.

Early Detection and Energy Efficiency

Not only do the multiple sensors provide a better idea of what’s happening inside the bin, but GrainTrac is set up to alert you of any distinct temperature changes which could be an indicator of spoilage in a certain area of your bin. Anytime a material spoils, it will give off heat.

The accuracy and timeliness of the data aids producers in addressing problems as they arise rather than dealing with them (and/or finding them) when the bin is unloaded. GrainTrac allows users to turn fans on/off remotely as an optional feature, saving energy while preventing loss of weight per bushel due to over-aeration.

GrainTrac puts grain management at your fingertips. Being able to track and see temperatures and temperature changes can help control energy costs, stop shrinkage, and protect grain quality and profits. Learn more about grain temperature management from our team of experts!